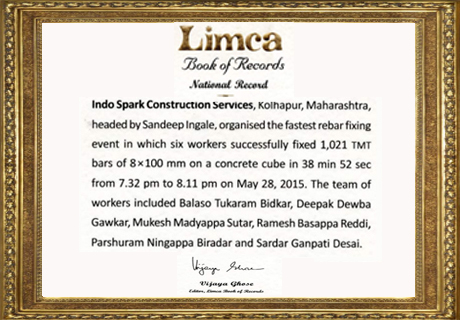

INDO CONSTRUCTION FASTENING SYSTEMS

ICFS Anchor Fastening Systems

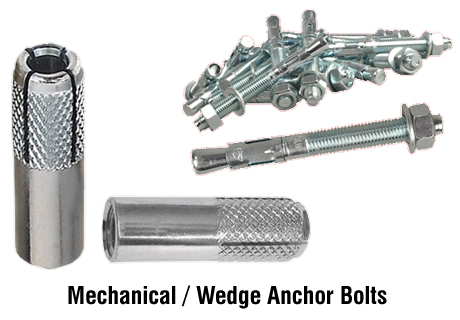

ICFS is an Anchor Fastener Brand offering comprehensive solutions with a range of products, with International Approvals. We have chemical and mechanical anchors usable for installing furniture at site. Based on the design load parameters, we even suggest correct type of chemical, Diameter of anchor bolts...