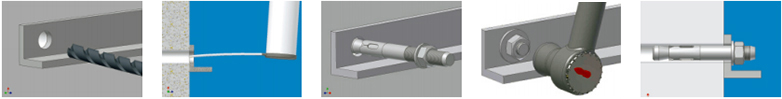

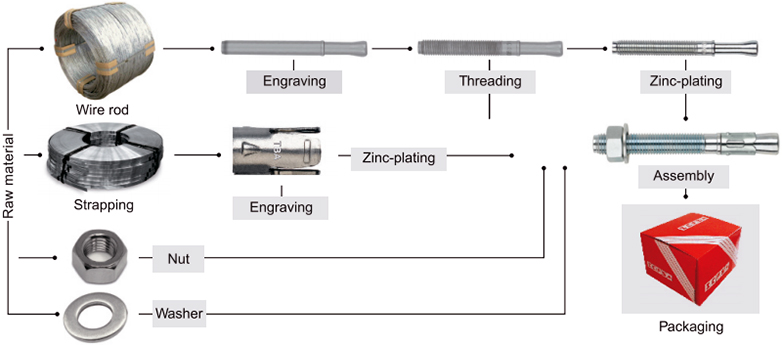

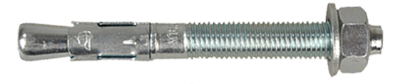

The through bolt anchor TBA can be installed through the work piece. This saves considerable time in installation avoiding alignment errors and provides an exceptionally efficient retention method for fixing to concrete and stone. Its firm fixing action permits repeated removal and replacement of the nut without weakening the anchorage. As the bolt is driven into the fixing hole the clip is compressed ensuring a tight interference fit. When torque is then applied to the nut the tapered section of the bolt retracts through the clip which expands to create a rapid and permanent grip. As for the internal threaded version TBA-I, it can be installed in normal drill holes without a setting tool.

• Roughness working principles; installation by controlled torque.

• Use for high loads

• Easy installation

• Use in non-cracked concrete

• Previous installation, or through the fixture

• Use for static or quasi-static loads

• Zinc plated version

• Variety of lengths and sizes, assembly flexibility

• Available in ICSF design software

• Structural applications in non-cracked concrete

• Safety barriers

• Billboards, machinery, boilers, signals, Steel beams,etc.

• Fixings wood structures in concrete